1600 Series Floating Brush Rotor

INCREASED EFFICIENCY & LOWER OPERATING COSTS

-

Proven energy savings of 30 to 60%

-

Higher O2 transfer and more mixing for less horsepower

-

Simple and predictable maintenance

-

Unique, maintenance-free UHMW bearings

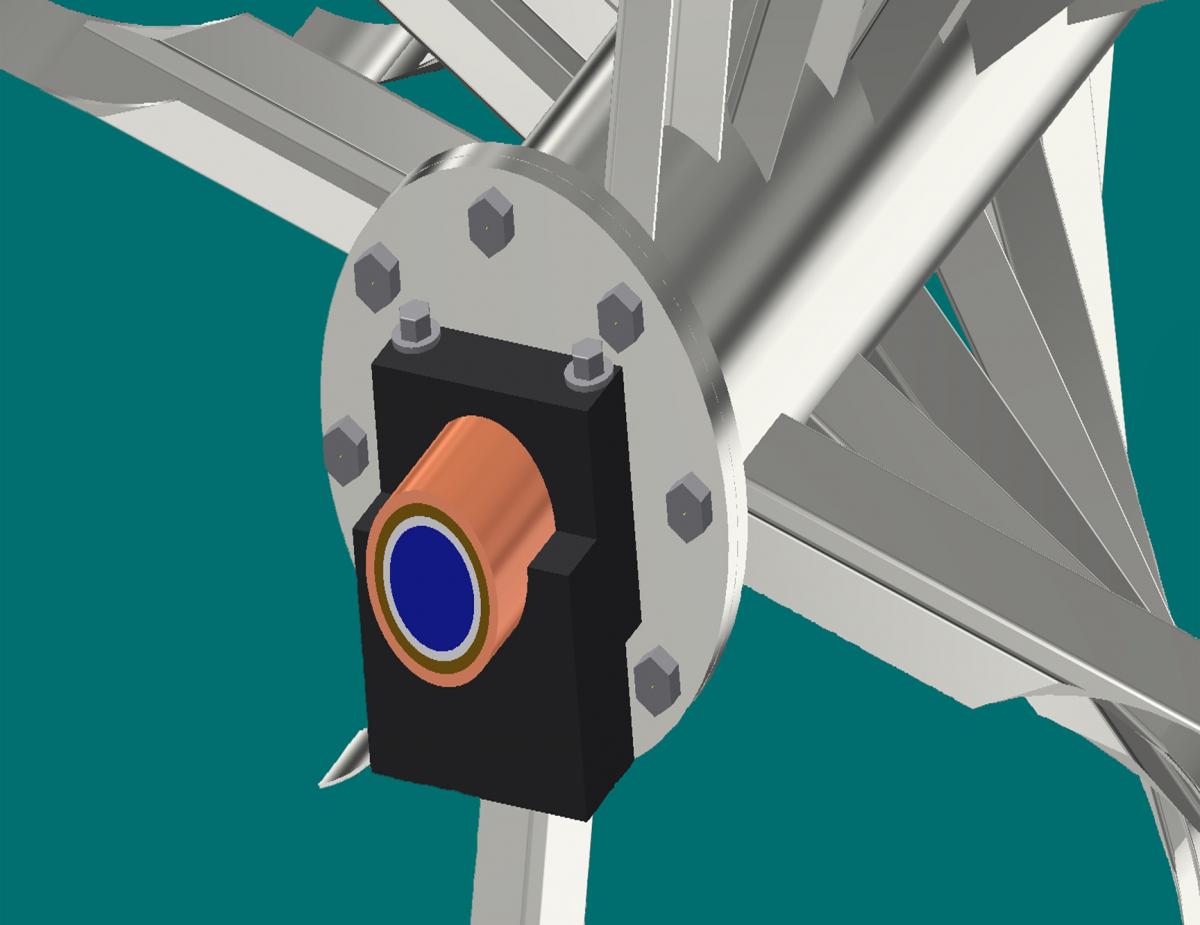

IN-LINE FLEX DRIVE

- Unique swing plate gear mount allows tri-axial movement to eleminate critical alignment issues.

- Elastomeric Coupling

- "Floating Shaft Seal" prevents migration of waste water along the shaft to the gear reducer.

- In-Line Flex Drive Illustration

"INNOVATION & MAINTENANCE PREDICTABILITY"

Shields

Provides unsurpassed protection for the gear reducer and motor from the surge of the rotor

1 - Motor Cover that Hinges up for Easy Access for O&M Inspections

2 - Vertical Splash Shield

3 - EVS Cap Guard

Maintenance-Free Bearings

- Years of maintenance-free operation

- No grease required

- * Click Product Information for more information on our bearing assemblies